Project information

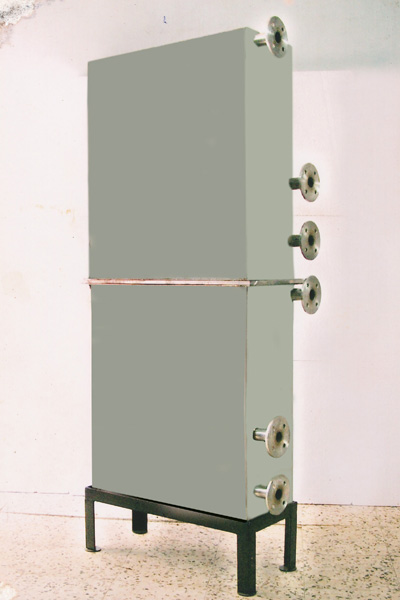

- Category: Liquid to Liquid Heat Exchanger

More details about Liquid to Liquid

Liquid-to-Liquid Heat Exchangers: Unlock Efficiency & Sustainability

In today's industrial environment, maximizing energy efficiency is crucial for both economic and environmental reasons. Liquid-to-liquid heat exchangers offer a powerful solution, capturing waste heat from hot process liquids and transferring it to cooler liquids requiring heating. This innovative technology translates to significant cost savings, reduced environmental impact, and a more sustainable operation.

How It Works

Imagine two streams of liquids flowing through separate channels within the heat exchanger. Separated by a highly conductive barrier, heat from the hot process liquid efficiently transfers to the cooler liquid, all without them ever mixing.

- Hot Process Liquid: This stream carries thermal energy typically generated as a byproduct in various industrial processes.

- Cool Liquid: This stream needs to be heated for various applications, such as preheating feedstock materials or boiler feed water.

As the hot process liquid passes through the exchanger, its heat is transferred through the barrier, effectively preheating the cooler liquid. This preheated liquid then requires less additional energy to reach its desired operating temperature.

Benefits of Liquid-to-Liquid Heat Exchangers

- Enhanced Energy Efficiency: By capturing waste heat from process liquids, these exchangers significantly reduce the overall energy consumption of your operations. This translates to substantial cost savings on your fuel bills.

- Reduced Emissions Footprint: By reusing waste heat, these systems minimize the need for additional fuel combustion to heat liquids, leading to lower greenhouse gas emissions and a cleaner environment.

- Improved Process Control: Consistent preheating of liquids with recovered heat leads to better temperature control within your operations, optimizing product quality and production efficiency.

- Wide Range of Applications: Liquid-to-liquid heat exchangers are versatile and can be integrated into various industries, including:

- Chemical Processing

- Power Generation

- Food & Beverage Production

- Oil & Gas Refining

- Pharmaceutical Manufacturing

- HVAC Systems (heating, ventilation, and air conditioning)